Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow or deep purple to rusty red. The iron is usually found in the form of magnetite (hematite , goethite, limonite , siderite .)

Ores containing very high quantities of hematite or magnetite (greater than about 60% iron) are known as “Natural ore” or “Direct shipping ore”, meaning they can be fed directly into iron-making blast furnaces.

Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel—98% of the mined iron ore is used to make steel.

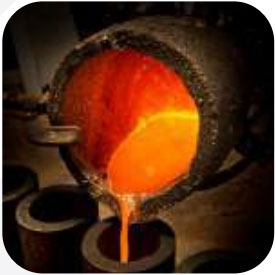

With appropriate pig iron , scrap and sponge iron are mixed together for melting purpose to get best quality steel.

The completely refined molten steel with the right chemical composition is transferred to the Continuous Casting Machine (Billet Caster) to change the molten steel to Solid Steel. This solid steel is known as Billet.

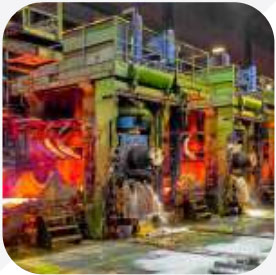

The billet which is out of the caster will be rolled directly on to the rolling mill stands. In each stand the size of the billet is reduced to finish product by size.

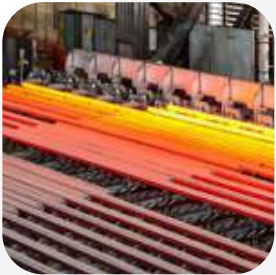

The finished product is passed through the system to remove the heat from the surface. This will allow the transfer of heat from the inner portion of the product to the outer surface. This balance of heat in the finished product will give a uniform change in the mechanical strength of the bars. The technology used in this stage is known as “THERMEX.”

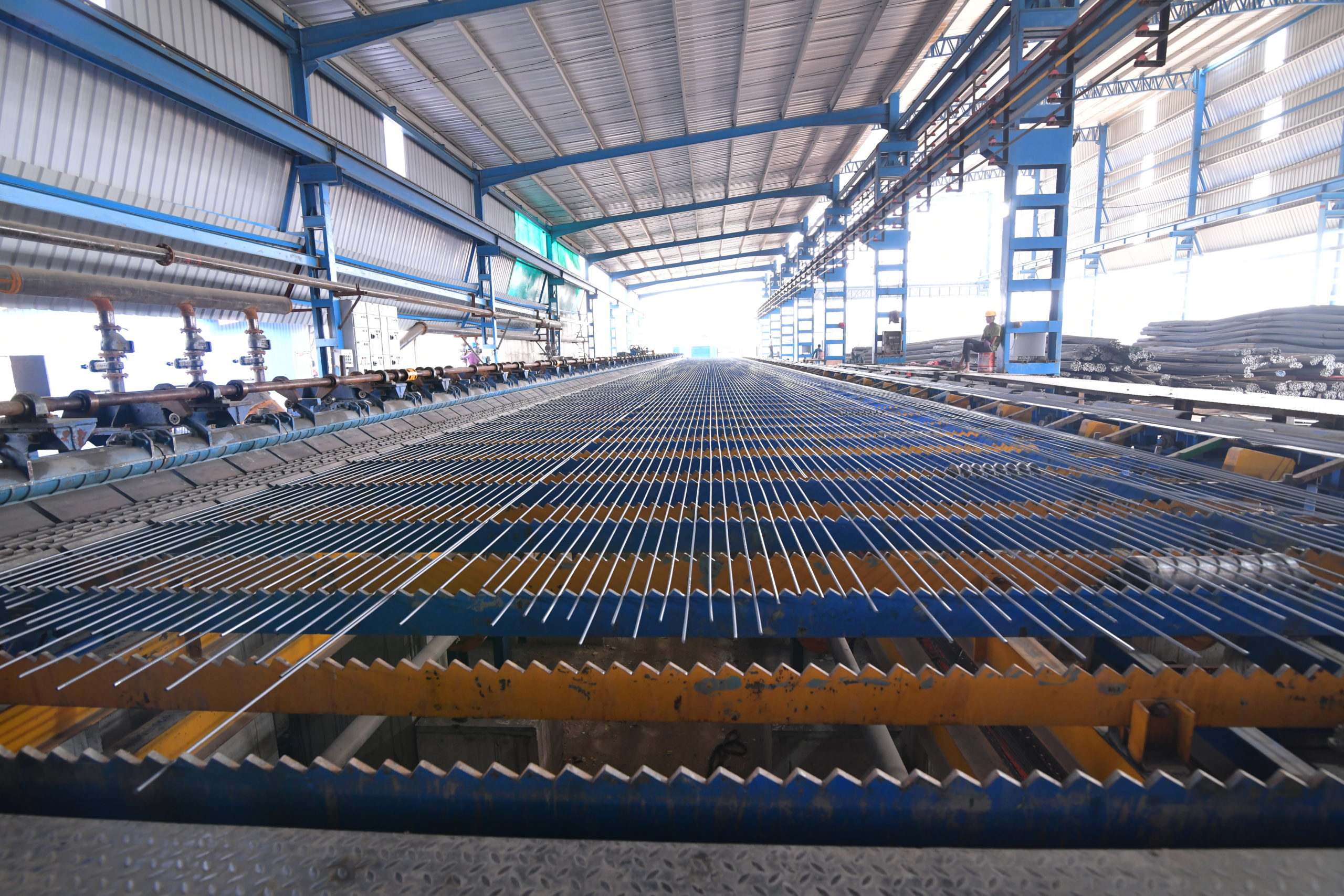

Self Tempering on Automatic Cooling Bed The bars after completing the Quenching stage will cool naturally on automatic cooling bed in the atmospheric temperature. This process is very important as the final product should balance the heat within itself to adjust to ambient temperature. This can be achieved properly by rake type cooling bed as bars are separated from each other at an equal distance. After this stage, the final product is known as TMT (Thermo Mechanically Treated) Bars.

Quality parameters are checked every half an hour to ensure the consistency in the TMT bars. Additionally, a regular audit is done by the personnel from the company who has provided THERMEX technology.

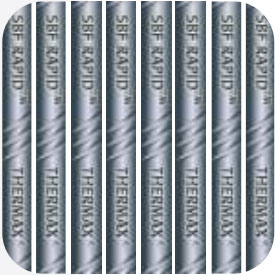

The TMT bars are then bundled, marked with a unique tag for identity of SBF RAPID TMT Bars. This final product is delivered to all the clients through our strong distribution network.

The Full Form of IQMS is Integrated Quality Management System. With IQMS we provide real-time manufacturing, production monitoring, quality control, supply chain management and customer relationship management.

To ensure the quality of our products, we also keep our focus on optimum use of natural resources, energy and energy sources. We continuously try to improve the working environment and integrated Quality management system of the company with the aim of reducing negative environmental impacts, as well as the number of traumas and accidents.

Rapid TMT bars speaks of the purity – Ore to Core of steel which provides “Advanced Outer Armour Shield ” that gives higher yield strength and ductility .

At SBF ISPAT , we are committed to provide the highest level of quality of TMT bars – “ SBF RAPID THERMEX Fe 550D ” .Our each bar is Physically and Chemically tested bar and we provide 100% satisfaction with test report with every dispatch.

We are committed to provide consistently high quality products that exceed customers expectations , accomplish profitable and sustainable growth with commitment towards social and environmental values.

And also to become one of the leading Quality TMT manufacturing company in India with latest technologies at an affordable prices.

SBF ISPAT is committed to practice highest standards of corporate culture and contribute towards India’s economic growth without harming the environmental balance. We produce GREEN STEEL.

Steel’s strength and durability can be tested using a variety of techniques.

Metallurgical testing is the process of putting steel through mechanical, thermal, or chemical procedures to evaluate its properties.

The goal of metallurgical testing is to gain a better understanding of the structure and makeup of the steel to predict how it will perform under various conditions.

The measurement alongside elongation as well as the decrease in the area of a tensile test can be easily used to make the assessment of the material’s ductility. In other words, material ductility can be defined as the amount of deformation that is feasible to the steel before fracture or failure.

The tensile test is used to assess how materials will respond to repeated applications of varying loads. It is used to model the kinds of stresses that naturally emerge in materials during normal service by Universal Testing Machine (UTM)

In corrosion testing, the material is destroyed through chemical, electrochemical, or metallurgical interactions with the environment. To mimic actual use settings, many sorts of environmental exposure tests are conducted.

To sum up, to prevent fatigue or failure of steel structures, quality steel is essential. Weakness may be the result of manufacturing issues, especially if the surface is folded or moulded.

Steel quality checks are a crucial component of steel quality control. Its goal is to ensure that the specifications’ requirements are being followed. A steel structure’s durability can be greatly diminished if the processes, procedures, and materials needed to manufacture it are not strictly followed.

At SBF ISPAT, we have a fully specialized and high tech ultra modernised Laboratory with latest equipment and dedicated team of chemical/metallurgy engineers.

Chemical Test by Spectrometer.

It takes around 10 to 15 seconds and then gives results in printed form of 26 elements in the TMT. It shows the result of percentages of Carbon, phosphorous and Sulphur and is necessary according to BIS. Percentages of copper, manganese and chromium are also given by the Spectrometer.

Bend the bar at 135° with prescribed Mandril & observe the behaviour of the rebar. Place it in 100°C hot water for 30 mins. Then again bend at 157.5° & again observe the behaviour of the rebar.

The result- The bar must bend without any crack formation.

Also one should check – Weight of Bar/Meter Length , ISI mark on each bar and thickness of bar which should be as per BIS norms.

At SBF ISPAT , we provide the highest level of quality of TMT bars – “ SBF RAPID THERMEX Fe 550D ” .Our each bar is Physically and Chemically tested bar and we provide 100% satisfaction with test report with every dispatch.